Design And Applications Of Powder Metallurgy Processes

Powder processing forms solid parts from material powders. It has been claimed powder metallurgy was used by the Egyptians 5000 years ago and in India 2,000 years ago, both in the manufacture of iron parts. Modern powder processing techniques began in the early 1800’s. Powder processing saw widespread use, in industrial manufacturing, in the early 1900’s in the production of Tungsten light bulb filaments. Modern industry employs many different powder processes. Parts from 50-100 lbs can be produced as the upper size limit typical in powder metallurgy. Most parts produced by these types of methods, however, tend to be under 5 lbs. Design and applications of powder processes are discussed in this section.

Design Of Powder Processes

Powder processes are suited to a specific and somewhat limited range of manufacturing applications. Due to the nature of powder metallurgy, a unique set of design considerations exist. In general, compaction and ejection from the die as well as powder flow during compaction are primary factors influencing the design of powder processes. Tooling is an integral factor in manufacturing process design. For example, parts requiring long thin punches should be avoided, since punch rigidity is critical.

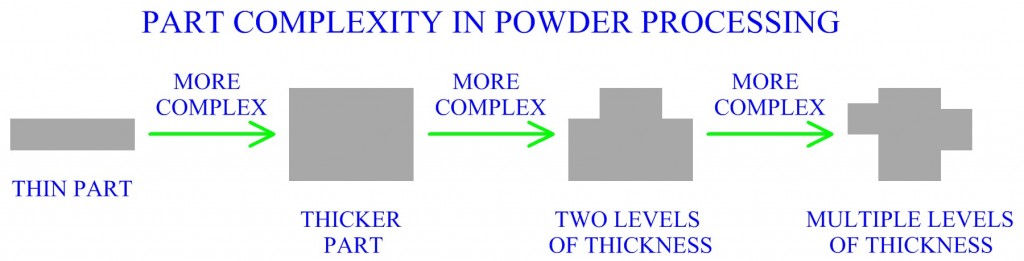

When designing a powder metallurgy manufacturing process it is most often advantageous to limit part complexity as much as possible. Powder metallurgy is most effective at producing parts with two dimensional profiles and uniform thickness. Increasing the thickness of the work causes an increasing difficulty obtaining uniform compaction of powders. Compression from both sides is often used to mitigate this problem. Another factor is that powder does not have a tendency to flow laterally within the die cavity during pressing. A part with more than one thickness will be more complicated to produce. As the number of different thickness values throughout the part increases, the difficulty of manufacturing that part goes up sharply. Manufacturing simpler designs can be done with one punch or two punches in opposite directions. Pressing from opposite directions is a method used for more complicated work as well, however with more complex parts, multiple punches with separate controls can be used. Machines with as many as ten individual actions have been employed in certain situations.

Part designs can be quantitatively measured for level of complexity by thickness values. The simplest part has a low uniform thickness and can be pressed from one direction. Next level of complexity could be considered a thick part of uniform thickness, requiring processing from two directions. Third level of complexity would include parts with two different thicknesses. Highest level of part complexity for powder metallurgy defines part designs with three or more different thicknesses.

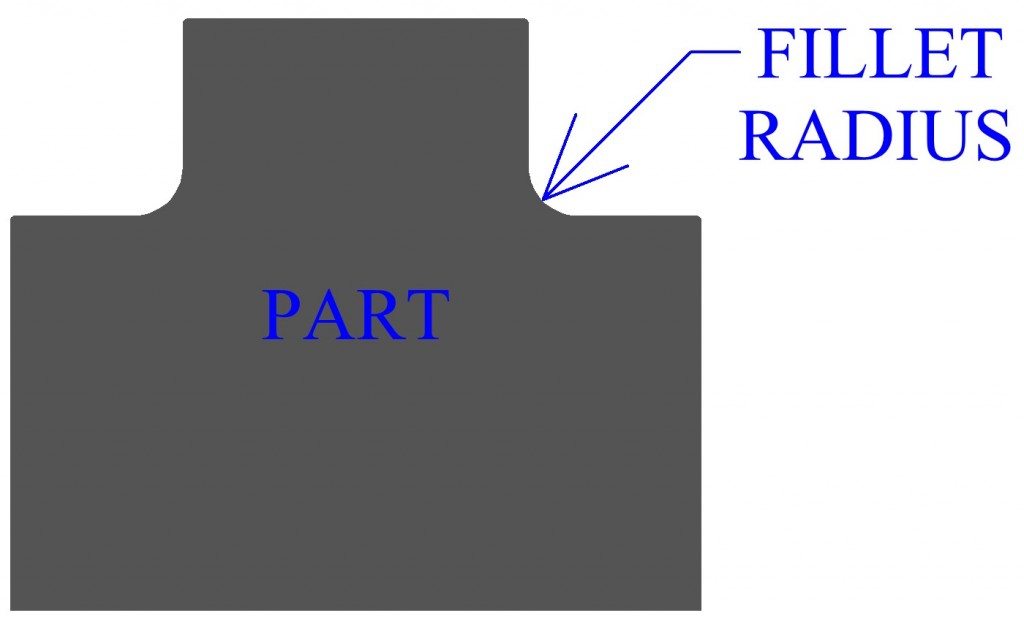

Tooling considerations make sharp corners in part geometry undesirable for powder processing. Fillet radius should be provided.

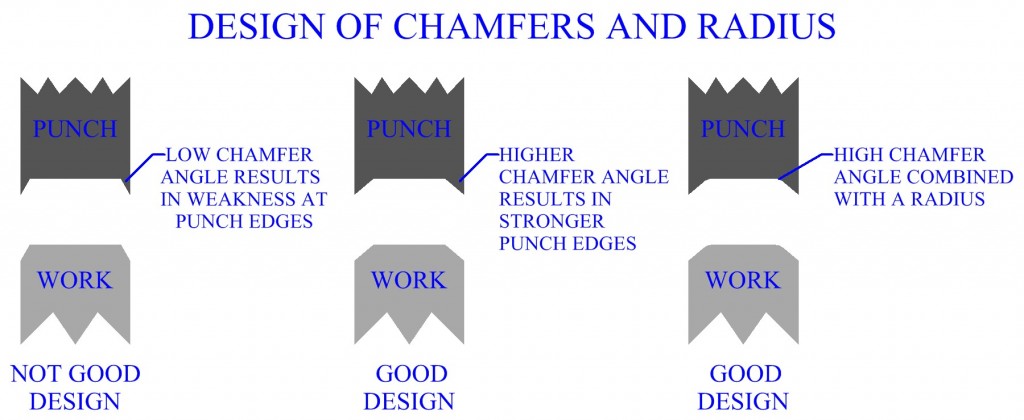

Corner radius should also be provided, if practical. However, if the outside radius will require the punch edges to be excessively thin, then another alternative should be used. Chamfers may be used in place of corner radius. Chamfers should be at an angle of 45 degrees or greater also to prevent punch edges from becoming too thin and lacking the rigidity required for the operation. Sometimes a radius can be combined with a chamfer.

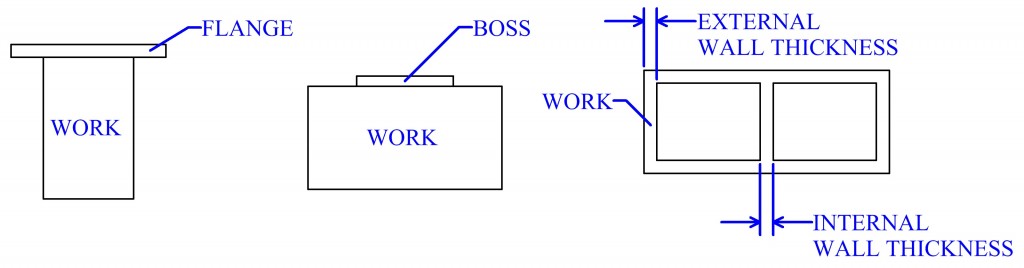

Specific geometric features may or may not be produced by powder processing. Features that can not be created are machined in latter. Threads for example, can not be produced in a powder processing operation. Flanges or overhangs on parts can be produced. Flange length should be minimized, because longer flanges on a green compact have a tendency to break, particularly during ejection. Bosses can be designed on powder metallurgical parts, but they should be as round as possible and not higher than 15 percent of the total part height. Wall thickness, either external or internal, should not be designed too low. Minimum wall thickness is typically around .06 inches, (1.5mm), but in some cases, parts with lower wall thickness than this have been manufactured.

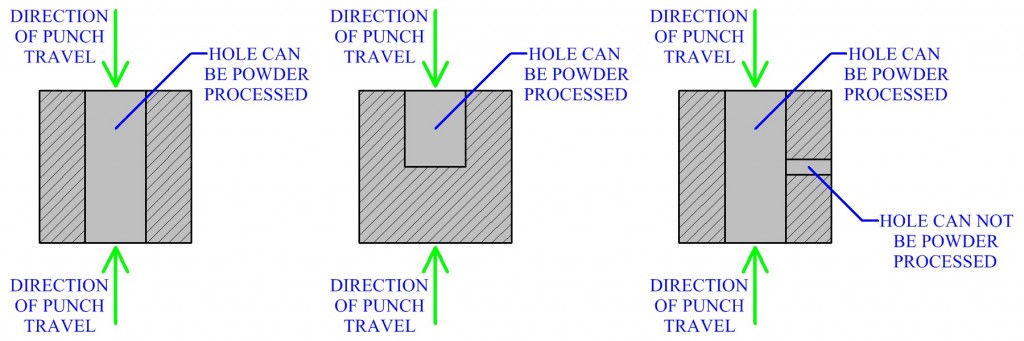

A wide variety of hole geometries and undercuts are possible with powder processing. Core rods are used to manufacture holes in the compact. The basic rule when designing holes and undercuts is that the feature must not prevent part ejection after pressing. Holes and undercuts should be parallel to the direction of pressing.

Applications Of Powder Metallurgy

Powder processing is best used for some specific manufacturing applications. Many factors make powder processing unique. An advantage of powder metallurgy is that very little material is wasted, as opposed to metal casting that requires a gating system that must be removed. In addition, much of this manufacturing process can be automated, therefore labor cost are low. For these reasons, powder processes become more favorable as material and labor cost increase. Expensive tooling, however, requires a significant quantity of parts to justify set up cost. Another disadvantage is that with conventional powder processing, the mechanical properties of the material are generally inferior to other processes. Tolerances for powder metallurgical manufacturing processes are moderate, typically .003-.005 inches. For these reasons, powder processing would be most competitive with other processes in the manufacture of large numbers of small parts, that do not require high mechanical strength or close tolerances. It is of note that further processing by forging and machining can improve the mechanical properties of the part and achieve excellent geometric accuracy. Also, some special alternative powder processes, such as hot isostatic pressing, can achieve superior mechanical properties on their own.

In addition to a more efficient, competitive manufacturing process, there is another branch of applications in which parts must be manufactured by powder processes because they would be difficult, or impossible, to manufacture any other way. The ability of this process to create a material with a controlled level of porosity is applicable in the manufacture of filters or oil impregnated bearings and gears. Refractory metals such as tungsten, that have high melting temperatures, can be formed using powder processes. Some super alloy and material combinations can only be achieved by powder processing. Cemented carbide tooling for components such as forming die and machine cutters, is manufactured using powder processing techniques. Other special applications of powder processing include friction materials such as clutch liners, electric contact materials, including switching and sliding contacts, cores for electronic systems and magnets.

Related Posts

-

Mercedes Vehicles Have Night Vision That Can Recognize Animals Now

Mercedes Vehicles Have Night Vision That Can Recognize Animals Now

Mercedes’ vehicles have had night vision capabilities, and

-

Pro/ENGINEER Interview Questions and Answers

Pro/ENGINEER Interview Questions and Answers

Pro/ENGINEER [Pro-E] 1. What is the difference between object

-

Thermit Process | Thermit Welding Materials | Application Of Thermit Welding :: TheMech.in

Thermit Process | Thermit Welding Materials | Application Of Thermit Welding :: TheMech.in

Thermit Welding Thermit welding is a fusion welding process

Leave a Reply