How computers have revolutionised our cars

Can computers simulate driving in a hurricane with a missing passenger door? Probably

Computer modelling is becoming an increasingly important part of car design, chopping testing times down to a fraction of what they were and enabling engineers to innovate and tinker with greater ease.

In fact, Mercedes-Benz performed computer modelling to test solutions for better aerodynamics in its new CLA, Chrysler is using state-of-the-art models to design better factories and Ford is analysing the MPG of a C-MAX Energi.

It seems computer modelling is here to stay in car manufacturing. Let’s see how this all works.

Chrysler builds a better powertrain factory

As we enter an age of connected devices and The Internet of Things, more and more data will be available to help automobile manufacturers build cars more efficiently. Computers already help track inventory, but Chrysler has developed new models that track where the specific parts are located in a factory, and even the motion a worker needs to perform to install the part.

Brian Harlow, the Chrysler vice president in charge of powertrain manufacturing, says the company now uses “world class manufacturing”. 3D models simulate safety, installation and risk analysis for the powertrain and engine assembly. “We want to make sure employees are not using extra time placing a part where it needs to go,” says Harlow.

One example is with a transmission sub-assembly. It might involve a cylinder that is 15 inches long and 8 inches in diameter. The company created computer models that show the exact placement in the factory and which motion will optimise the installation. Workers can see exactly how the part should be installed, where, and with which motion.

Harlow says this is just the beginning. In the future, Chrysler might create models that go much further, showing how the parts were obtained and delivered to the factory and even modelling what happens after the installation and how the part can be optimised for the longest life in the vehicle – including which materials to use for those components.

Interestingly, while this “world class manufacturing” is designed to model factory assembly, the goal is to optimise the installations for humans, not robots.

“There is an intellectual property you get with humans that you don’t get with robots. Robots only do what you program them to do. A human worker can avoid damage to expensive parts and give feedback about the safety handling and ergonomics involved with the installation,” says Harlow.

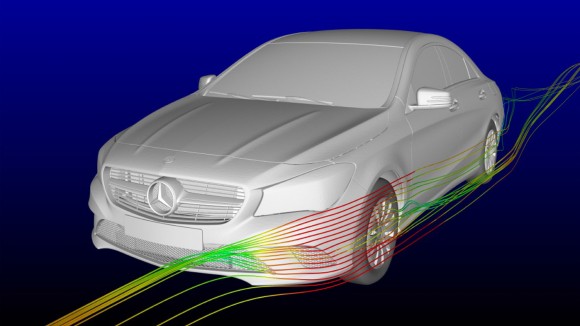

Mercedes-Benz tests aerodynamics of the CLA

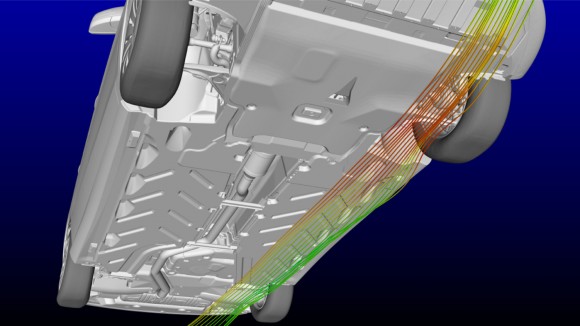

This compact four-door car from Mercedes, new for 2014, was designed in a vacuum – well, in a way. Designers turned to virtual aerodynamic testing (essentially, a computerised wind tunnel) to make sure the vehicle would hit their targets for styling and energy efficiency.

“Using CFD data (computational fluid dynamics) we get a better understanding of the airflow around the vehicle and especially through the vehicle, like cooling airflow, airflow in wheel arch housing and underbody,” says Patrick Höfer, who leads the Mercedes-Benz aerodynamics compact cars team that worked on the CLA.

Höfer says Mercedes generates what he calls “flow visualisation pictures”, which reveal problems in the aerodynamics. The company can see every streamline on the car and the physical data it needs for efficiency, such as pressure distribution and wake structure.

One of the specific areas they analysed was the airflow around the front wheels. “The results are noticeable in the shape of the front wheel spoiler and in the serrated wheel arch liner,” he says. “Due to the optimisation, the airflow goes under the whole front wheelhouse cavity, which helps to have a better working diffusor downstream. The front wheel spoiler works like a deflector of a sun roof, where the teeth create longitudinal vortices to help stabilise the shear flow [the force caused by a gradient] over and under the cavity.”

Höfer says there is a magnitude of data available to designers beyond what would be possible in a traditional wind tunnel. The idea is to weed out variables on the computer, and then to verify the virtual testing with a physical prototype, to be more efficient.

“In the wind tunnel we just have the smoke probe and wool tuft test to visualise airflow, which makes it quite discrete,” he says. “By using the CFD data intensively, we can analyse and optimise every single streamline, which also helps us in the wind tunnel testing to be more efficient.”

The result is that designers can correlate a drag coefficient value directly to mileage. For example, on the specific Mercedes CLA 180 Blue Efficiency edition, Mercedes knows that a 40-count (0.040) value correlates to an increase in 0.4 miles per gallon.

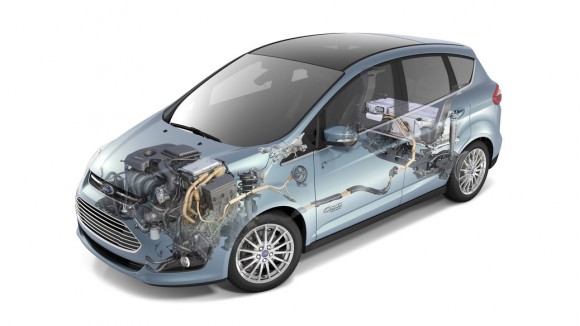

Ford models fuel efficiency in the C-MAX Energi

Computer modelling to determine MPG has evolved recently. In the past, there might have been a model of the combustion system itself, plus the transmission, the battery and related components. Another model might analyse the climate control settings and aerodynamics. Each model lived separately – engine models would maximise efficiency, for example.

Computing power has advanced to enable increased fidelity. One model is still not used to predict total results, but the models are correlated to arrive at an MPG rating.

Dr Mazen Hammoud, the chief engineer of powertrain electrification at Ford, says the company tries to predict the average user at various speeds. On a plug-in, the model has to account for the charge habits of the user – how often they charge up and for how long. Ford models a user who might charge only at the shops each day versus charging only at night.

“Modelling at the vehicle level – underhood temperature and aerodynamics – the interactions between different systems in different driving conditions are subject to assumptions in the model. At 60mph the aero drag is different from at 80mph, for example.” he says.

Another variable has to do with the warm-up process in the car. This is where models get complicated: a driver might be taking several short trips in one day versus another who starts the car once, drives to work, and then drives home later in the day. Warm-up involves lubrication for moving components, the transmission, engine and climate controls. All of the components require energy, not just the direct power to propel the vehicle.

“All energy used comes from the fuel or from the power utility,” he says. “This even includes using the heated seats or adjusting the seats. We try to re-generate energy, but to start with, all energy comes from these two sources. All energy you use can reduce mileage.”

The Ford C-MAX Energi is rated at 41MPG on the highway, but 100MPG in combined electric and fuel power. The fully charged engine can run as fast as 85mph and can go 21 miles on pure electric power. The driver can also select a hold mode for EV that enables you use it later – say, when you will be driving in the city at lower speeds and want to take advantage of that power source.

“What we have the most data on is what we have in a lab,” he says. “It is the most controlled environment. Noise factors such as wind and warm-up have not normally been accounted for in models. As we learn more about plug-ins and how they are used, we are working on developing more models but we are not there yet. We will correlate these findings to the actual driving and experimental data. Unless it is correlated, it is useless.”

Ultimately, the models will look at all values inside the car – from the heated seats to the transmission temperature – and generate one number. For now, the data helps create an average that is predicated on real-world testing to verify the lab findings.

Leave a Reply