MANUFACTURING PROCESS – POWDER METALLURGY

Powder metallurgy is the manufacturing science of producing solid parts of desired geometry and material from powders. Commonly known as powder metallurgy, it may also be referred to as powder processing considering that non-metal powders can be involved. Powders are compacted into a certain geometry then heated, (sintered), to solidify the part. The manufacturing advantages and disadvantages, as well as the applications for parts produced by this method, are discussed latter in the design and applications of powder metallurgy section.

The first consideration in powder metallurgy is the powders used for the manufacturing process. Several different measures are used to quantify the properties of a certain powder. Powders can be pure elements or alloys. A powder might be a mixture of different kinds of powders. It could be a combination of elemental powders, alloy powders, or both elemental and alloy powders together. Material and the method of powder production are critical factors in determining the properties of a powder. It should always be remembered, when working with powders, that the powder itself may be a potential hazard. Some powders may be flammable and/or present health risks to workers. Safety precautions should always be taken when handling or storing powders. Also, be sure to follow any regulations regarding the handling, storage, or disposal of powders. Powder selection and processing will depend on cost, desired purity and mechanical properties of finished product. Environmental control is critical in proper storage and handling of powders. Contamination of powder can result in powder degradation and should be avoided. Remember, high surface areas cause powders to react readily with outside materials. This can have various results, oxidation for example, caused by oxygen present in the air.

Powder Properties

Powders are finely divided solid particulates. The size and shape of individual particulates is important. Characteristics of a powder can be quantified in several ways. These characteristics are necessary to understand when selecting a powder for an operation, since powder properties will affect processing factors.

Size And Distribution

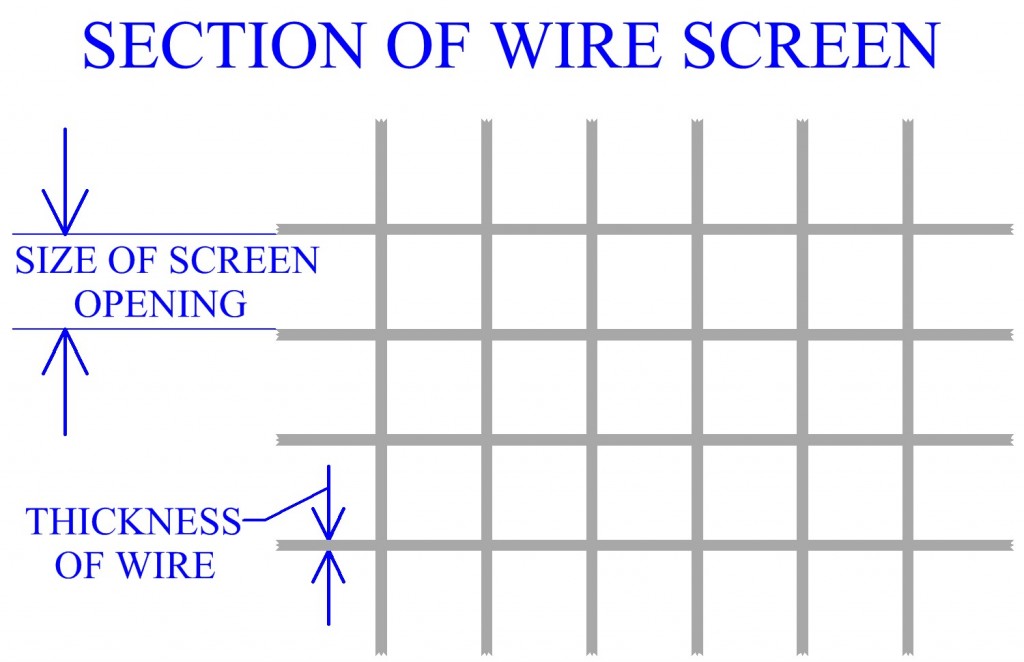

Size of particles is a factor that will affect processing of metal powders. In manufacturing practice, powders are commonly measured using a series of screens with different sized openings. Each screen is a wire mesh with openings ideally of the same size. Screens for powder measurement are designated according to the number of openings per linear inch, (i.e. 30, 100). Openings per linear inch are the same in the 2 dimensions of the screen’s surface, therefore the number of openings per square inch is the square of the linear number. A screen with a linear measurement of 100 has 1002 or 10,000 openings per square inch. When determining the size of an opening, the size of the screen’s wire must also be considered. Mesh opening size, (MS), can be determined by

MS = 1/MC – WS, where MC is the mesh count, (openings per linear inch), and WS is the thickness of the wire.

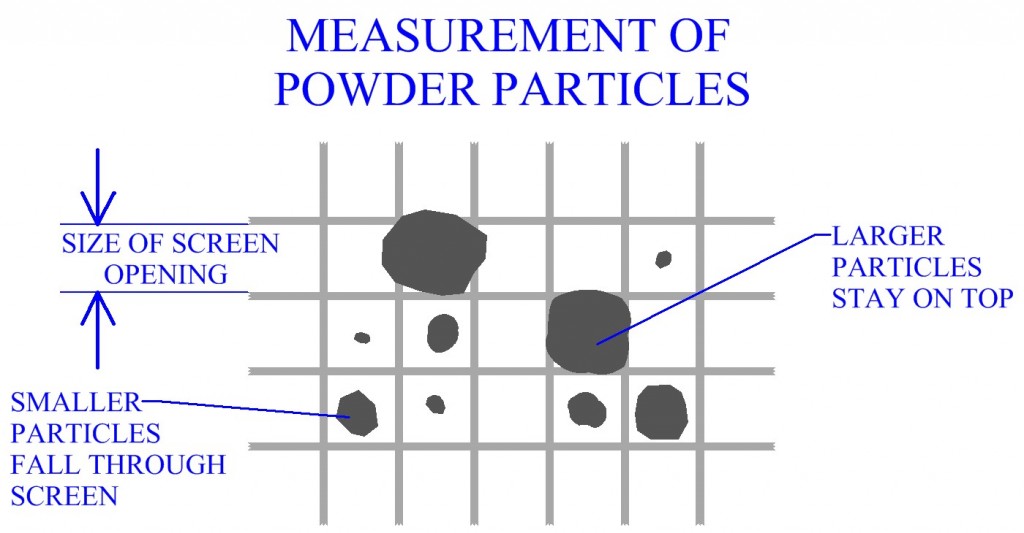

The concept of powder particle measurement using a screen is quite simple. When powder is poured on the surface of the screen particles that are smaller than the screen opening will fall through, while particles that are larger than the opening will remain on the top of the screen. In this manner a single screen can separate all particles in a powder above a specific size, from all particles in that powder below that size.

These screens are stacked one over another with the screen with the largest openings on top. As the stack progresses downward, each sequential screen has a smaller opening than the one above it. A powder sample is poured on the top screen. A machine vibrates the stack. Powder particles will fall through the screen openings until they encounter a screen size too small to fit through. Thus, each screen will collect metal powder particles of a certain size range. The sizes and distribution of sizes can then be measured. For example, the particles that pass through 90 but not 100 are said to have a size of 90-100, they may also be considered to have a size of 90. With this method particle size distribution can be measured, usually by weight percent, and quantified. Results can be represented graphically, the size range in which the highest weight percent of particles occur is called the mode size.

This system does have limitations. Imperfect screens can result in variations in the size of openings. Differently shaped particles also affect the accuracy of the powder screening technique. The difficulties involved in manufacturing screens go up in magnitude as the number of openings per inch increases. For this reason, powder particle size measurement using screens is limited to a lower range of about 400 opening per linear inch. Very small powder particles tend to agglomerate or stick together, which would make the metal powder screening method ineffective at extremely low ranges anyway.

There are several other methods by which particle size can be determined. Particles are suspended in a liquid medium and can be measured by light scattering techniques or by electrical sensors. Measurements can be made with a microscope. Other types of optical analysis may be used. X-ray measuring techniques are available. Sedimentation is also a method employed in manufacturing to measure powder particle size and distribution. Sedimentation determines size by measuring the sinking of particles in a liquid.

Particle Structure

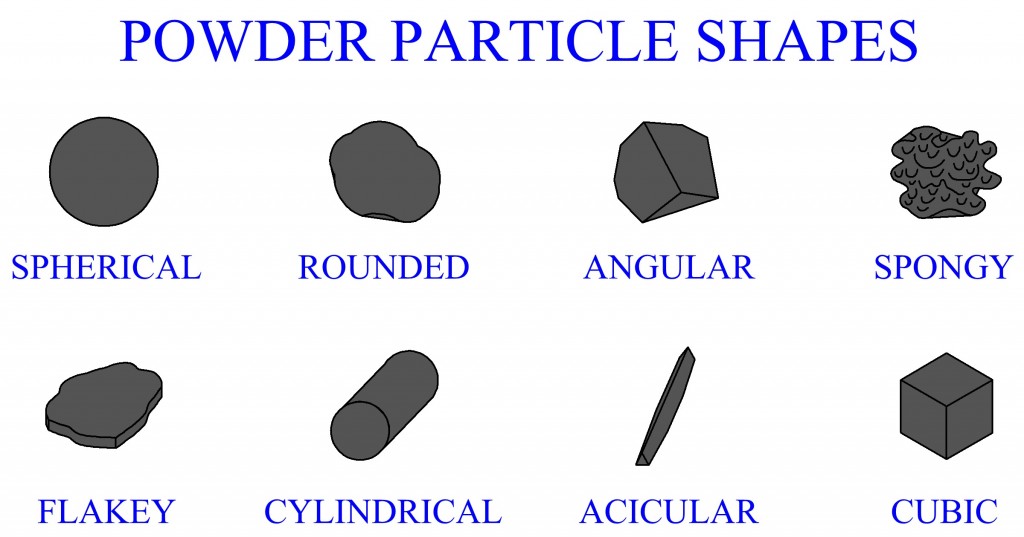

The structure, or shape, of particles is a major factor in a powder processing operation. Material and method of powder production are the main variables determining powder shape. Particles of a certain powder may have similar shapes but no particle shapes are exactly the same. Hence, there will exist a shape distribution within a powder. Different types of powders combined together may also have significant differences in particle shape, which will show in the shape distribution.

Particle shape plays a large roll in powder density and flow characteristics, it is also a major factor in pressing and sintering. There are several types of basic powder particle shapes. These are ideal shapes, particles in reality are imperfect and may exhibit characteristics of more than one shape type.

Two ways used, in manufacturing analysis, to quantify the shape of particles are the shape index and the aspect ratio. Shape index relates the particle’s surface area to the particle’s volume and compares that to a sphere, which has the lowest shape index. Aspect ratio is the ratio between a powder particle’s greatest dimension and its smallest. A perfect sphere will have an aspect ratio of 1, a rounded particle may have an aspect ratio of 1.5, while acicular or flakey particles may easily have aspect ratios of 3, 5 or 10.

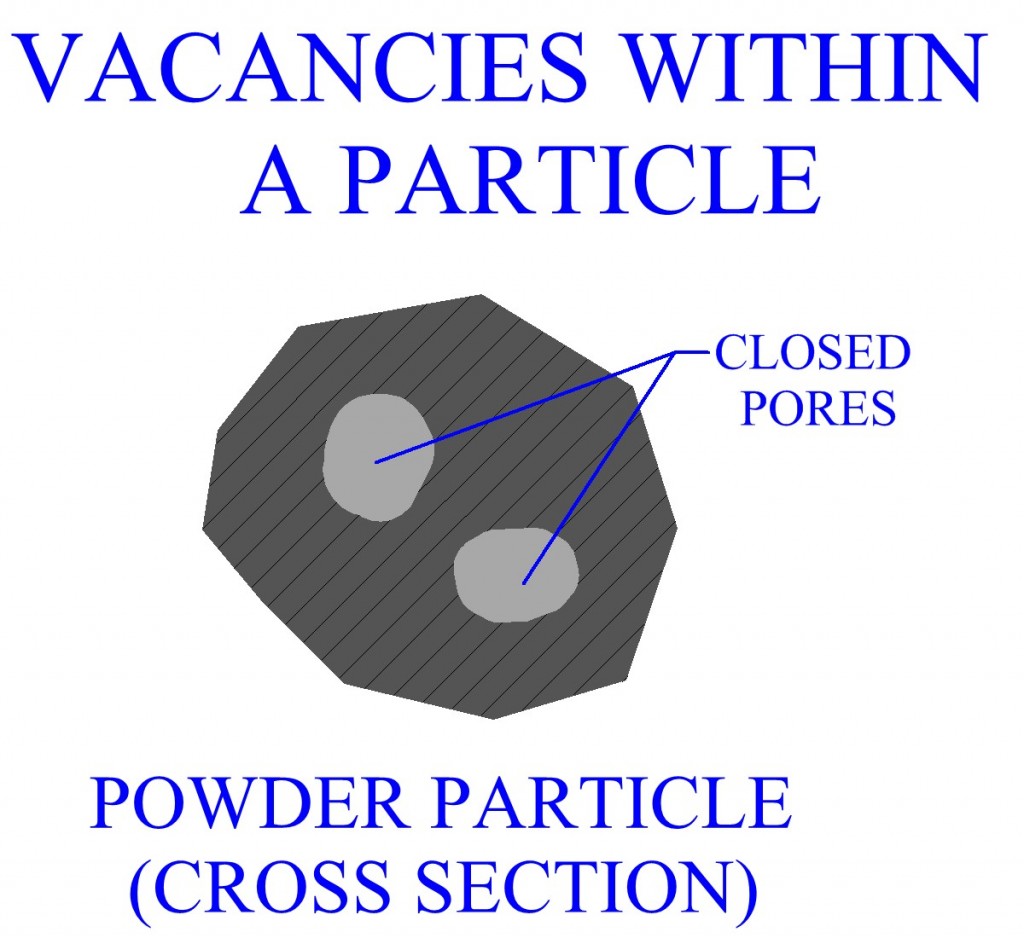

Porosity

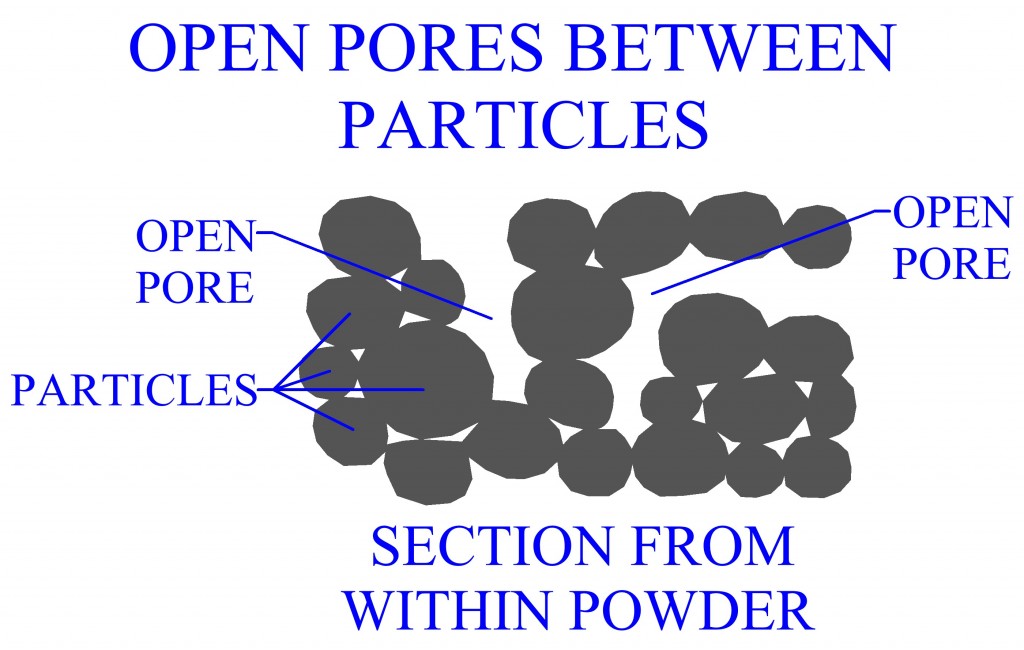

Pores, or space, within the powder is in a large part determined by particle shape, (and size), since the shape dictates how particles will contact each other. Spaces that exist between particles of a powder and are open to the outside are called open pores. These spaces expose external surfaces of powder particles.

During compaction of powder these spaces are eliminated. If any amount of this space remains after processing, it will result in porosity in the manufactured part. These open pores are permeable to the atmosphere. They are also permeable to fluids in general, such as liquid lubricants, water, or melted polymers, provided that the porous regions are interconnected and not isolated. The other type of vacancy that exists in a powder material is called a closed pore. These pores are not open to the outside atmosphere. Closed pores can develop during the pressing and sintering process if an open pore region becomes closed off. Another type of closed pore exists within the material of the powder particle itself. Theoretically if all the open pores and closed pores were eliminated, the density would be that of the fully dense material.

Friction And Flow Of Powders

The ability of a powder to flow will differ, depending upon the properties of that powder. Material flow will involve movement of particles over one another. Factors determining the ability of a particular powder to flow are particle size, particle size distribution, particle structure, particle surface, presence of moisture, material(s) and lubrication. Characteristics that decrease inter-particle friction will tend to increase a powder’s ability to flow.

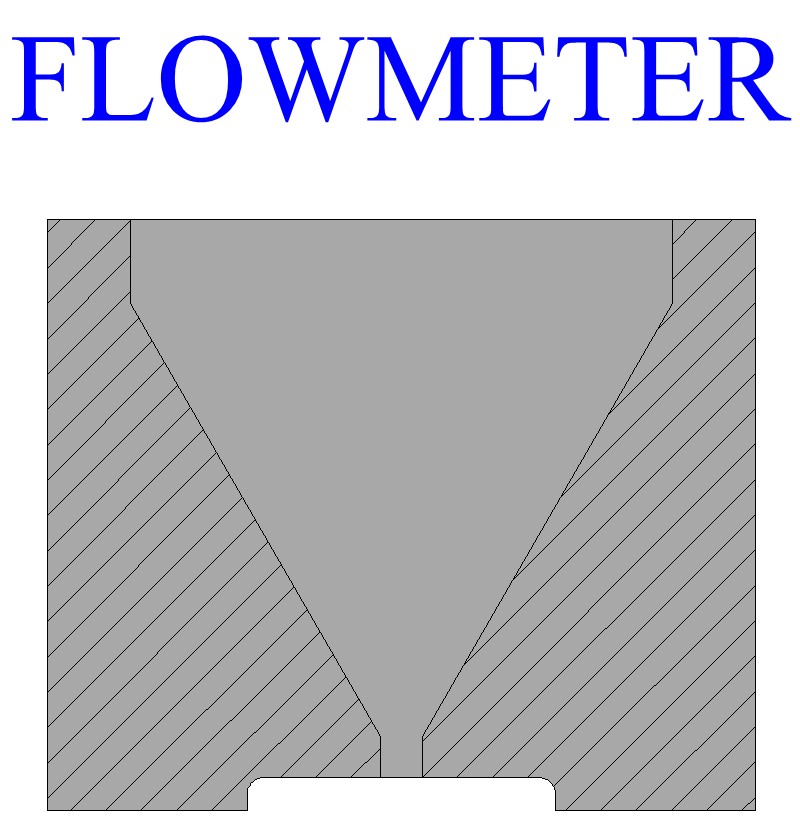

Better ability to flow is usually preferred for a manufacturing powder. More ability to flow results in faster powder flow rates. Faster rates will decrease die filling time, providing a higher production rate. Powder flow is important during the compaction of the part. Powder with poor flow characteristics may result in uneven compaction, meaning greater compaction of powder in some areas and less in others. Thus causing density variations within the pressed part. One way to measure flow rate is a flow meter. A flow meter is essentially a conical funnel with a wide opening on top and a smaller opening on the bottom. A certain amount of powder is poured into the funnel and gravity causes the powder to gradually flow downward through the funnel. Flow meter sides are set at a certain angle. The time that it takes for all the powder to flow through the flow meter is measured and flow rate is computed. This is a relative measurement to other powders.

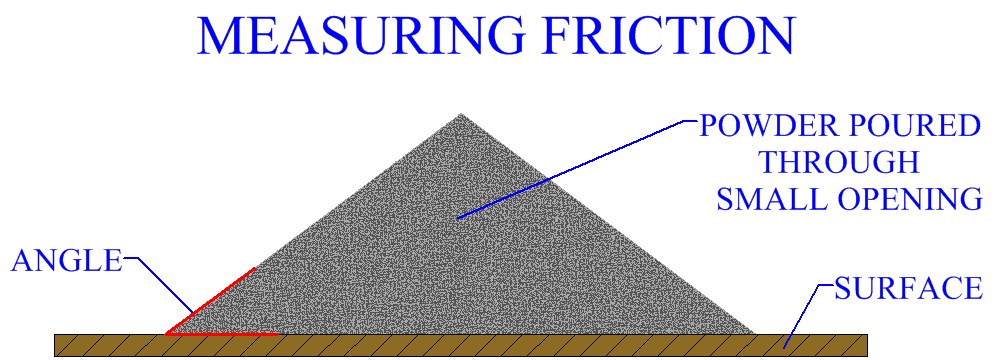

Friction is an important consideration and has a large effect on flow and compaction. As mentioned, friction tends to decrease powder flow ability. Friction occurs between the surfaces of the powder particles. Friction also occurs between the particles and the equipment. Lubrication is used in manufacturing to reduce friction. Excessive friction can impede the consolidation of the powder resulting in disproportionate compaction, density and porosity in the work. Smaller particle size usually results in greater friction. Generally, particles with spherical shapes exhibit lower friction and friction increases as the shape becomes less spherical. One test for friction is to pour powder from a container through a narrow opening onto a flat surface, forming a pile. The angle between the side of the pile and the surface is considered. Greater angles will indicate more friction within the powder.

Powder Chemistry

Chemical composition of the powder should be known. Powder chemistry is a major factor in manufacturing process design. Individual particles must be examined. Metal powders can be a pure element, a mixture of different elemental particles, or the particles themselves can be an alloy material, called pre-alloyed. Powder metallurgy is unique in its ability to alloy or combine materials that otherwise could not be produced by any other method. Often different materials are powdered and combined as powders. In this case individual powder particles will be all of one type of material or another. The particles will have different characteristics as well. The alloying of metal powders of different materials occurs latter during the sintering of the part. Sometimes nonmetallic powders, particularly ceramic powders, are mixed and combined with other materials.

Chemical composition of the powder can typically be determined using standard testing procedures. Some tests unique to powders may also be used. For example, an iron powder may have an unknown percent of iron oxide, (Fe2O3). A test sample of the iron powder is taken and exposed to a stream of hydrogen. Weight loss that occurs in the sample is measured. From this, the percentage of iron oxide present in the powder can be calculated.

Surface chemistry of powder is critical, due to the high surface area to weight of powders. Oxides may form on particles and should be avoided. Organic materials or silica can develop surface films on powders. Moisture can permeate through open pores and substances within the water can react with particle surfaces, creating films. Surface films are undesirable in manufacturing powders. Typically they are rubbed off by particle motions during compaction and form inclusions in the material.

Surface Area

Surface is measured by considering the combined surface area of all the particles and relating that to the volume of powder, (usually cm2/g). Powders have an extremely high surface area to volume ratio. Surface area to volume increases as particle size decreases. Particle shape also is a factor in surface area. The higher the surface area, the more activity that will occur during sintering. There are advantages and disadvantages to increased surface area of powders. Increased surface area will increase the area for oxides and other surface films to develop. Also agglomeration, or the sticking together of powder particles, tends to occur in smaller sized particles. Smaller particles are advantageous in that they provide more uniform material distribution in the manufacturing process and better mechanical properties in the product.

Bulk Density

Bulk density is the density of the powder in its loose, uncompressed form. A container of known volume is filled with the powder. The powder is then weighed and the density is determined, usually expressed in g/cm3. Major factors determining bulk density of a powder are particle size, particle size distribution and particle shape.

True density of a material would be the density of the mass if the powder particles were melted and formed into a single piece. During the compression stage the particles are reshuffled, becoming generally closer together as inter-particular pores are eliminated. As the powder is compressed its density increases. In order to process a powder to its true density all porosity open and closed must be eliminated. The difference between open and closed pores is discussed above, under porosity. Conventional powder processing does not achieve elimination of all porosity. Several special powder processes, discussed latter, attempt to produce parts closer to 100% true density.

Packing factor is the bulk density of the powder divided by the true density of the material. Common packing factors used for manufacturing parts might be .5 or .7. Porosity indicates the amount of empty space within the material. Porosity is expressed as the percentage of total volume that is empty.

Compressability, Compactability, And Sinterability

Compressability indicates the relative ability for a powder to compress. For example, lubricants can improve compressability. Compactability is not the same as compressability. Compactability is a measurement of the structural strength of a compacted, unsintered powder, (called a green compact). Binders, for example, can increase the compactability of a powder. Sinterability is the ability of powder particles of the green compact, to bond together when heated during the sintering process. Sinterability is dependent to a large extent on surface characteristics of the powder particles.

Powder Production

The production of powder of different materials is an essential first step in powder metallurgy. Method of production is important, different powder materials are produced differently. Particle structure characteristics such as size and shape will also be dependent on production method. Some materials are produced with more than one technique. Industrial manufacturers that produce powders are usually different than those involved in powder part manufacture. Atomization is the most popular method of powder production. Other methods include reduction, carbonyl decomposition, precipitation from solution, mechanical, condensation and electrolic deposition.

Mixing Of Powders

Before processing it is desirable to create a homogeneous, or uniform, distribution of all the different material constituents within the powder mass. Uniform distribution of powder particles is important in helping to obtain uniform density within the processed part. Constituents within a powder material ready for processing can include, powders from one or more materials, lubricants, deflocculates and binders. Lubricants improve flow characteristics of powder particles, deflocculates help stop agglomeration of particles and binders help improve compactability.

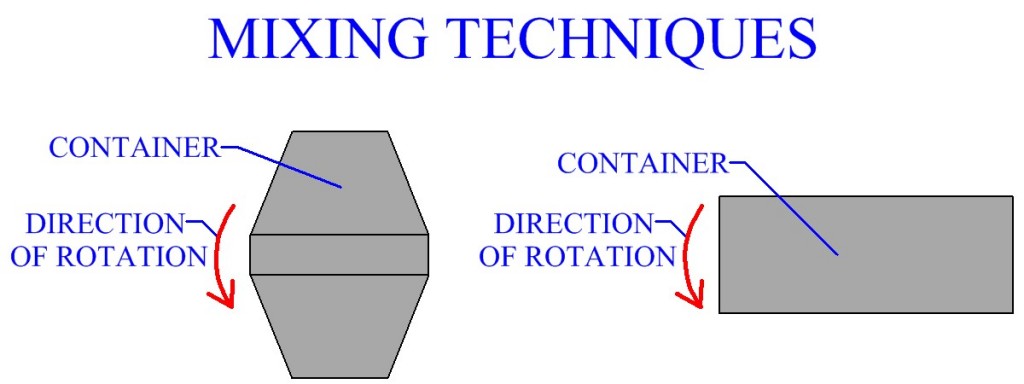

Blending is different from mixing, as it is in reference to uniformly distributing particles of the same material. Blending achieves uniform size and shape distribution of particles within a powder. Mixing refers to combining and homogeneously distributing particles of different materials. Individual powder materials are often blended first, then mixed with other powders. Mixing is performed by a variety of mechanical methods. Common techniques used in manufacturing are rotating containers, such as drums or cones, and stirring mechanisms.

Containers are usually less than half full of powder during mixing. Mechanisms are designed into the mixing containers to prevent free fall of powder. Vibration of powder during mixing should also be avoided. Free fall and vibration of powder will cause segregation of particles, which is the opposite of uniform distribution. Amount of time that powder is mixed will depend on specific process factors. Powder mixing time could be on the order of minutes or days, an hour is an approximate typical mixing time in industrial powder processing. Length of time should be sufficient to achieve uniform distribution of materials, but should not be longer than needed. Over mixing can decrease particle size, alter particle shape and work harden particles. Atmosphere is also sometimes controlled during mixing to help avoid contamination, such as the forming of oxides on particle surfaces.

Related Posts

-

Solar Energy Materials And Solar Cells | Types Of Solar Cells :: TheMech.in

Solar Energy Materials And Solar Cells | Types Of Solar Cells :: TheMech.in

Solar radiation received on earth in just one hour

-

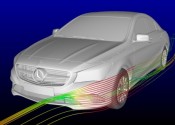

How computers have revolutionised our cars

How computers have revolutionised our cars

Computer modelling is becoming an increasingly important part of

-

These Incredible New Buses Are Charged Wirelessly by the Road Itself

These Incredible New Buses Are Charged Wirelessly by the Road Itself

Imagine an electric vehicle that can travel endless

Leave a Reply