Gorilla Glass Manufacturing Process | Gorilla Glass Strength Test | Gorilla Glass Molding :: TheMech.in

Touch screen technology in fast few years has grown drastically in various applications, in order to overcome the difficulties faced by the touch screen; a new frontier technology has to take its part to revitalize the use of touch screen. In this counterpart gorilla glass has thrown a flash light focus on touch screen technology. Gorilla Glass has taken an apt plays in touchscreen technology. This scratch repellent glass is used to form touchscreen panel for portable gadgets like ATM machines, android mobile phones, tablets, personal computers and MP3 Players. It’s designed to protect display screens from scratches, sticky oils, fractures, etc,.

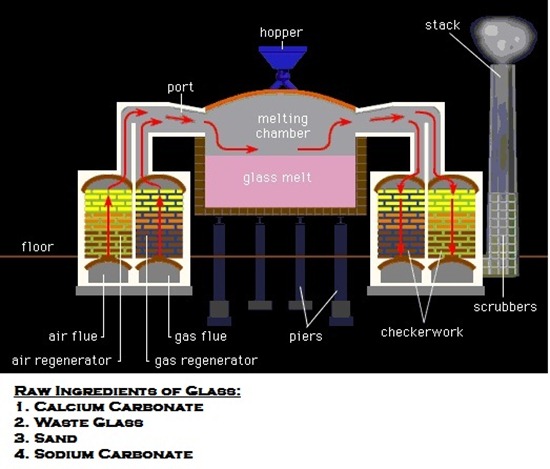

Process 1: Melting the glass

-

The Silicon Dioxide is mixed with other chemicals then put into a furnace to be melted

-

Oxygen and Hydrogen injected into the furnace to increase the heat transfer making the material melt faster

-

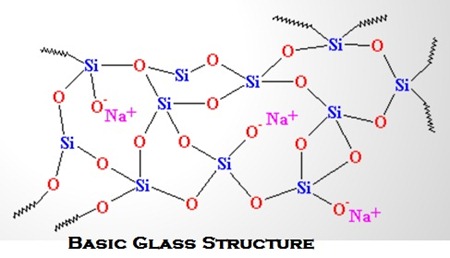

Resulting glass(Alumino – Silicate) Contains Aluminium , Silicon, Oxygen , Sodium ions

Process 2: Mold the Glasses

-

The molten glass is poured into the desired die and the required shape and thickness obtained.

Process 3: Ion Exchange

Manufacturing Process:

Gorilla glass starts as a mix of pure sand (silicon dioxide) and naturally occurring chemicals (resulting glass is termed as alumino-silicate) which splits the impurities and melting the sand. The molten glass fills up the bin and it is overflowed on each facet. During this “fusion draw” method, the resulting molten glass is pull down by a robust process to a long of 0.59 millimetre-thick sheets of Alumino-silicate Glass.

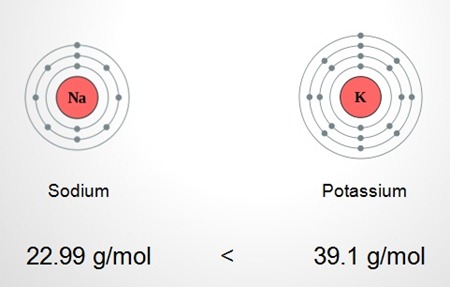

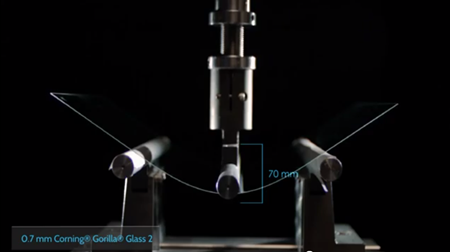

At this point, you have some very huge sheets of clear, clean, pure glass, however it’s not much stronger than regular glass. Gorilla gets its strength through a noteworthy action. Currently the glass sheet is dipped each into a molten salt bath where a chemical exchange happens. Potassium ions are infused into the glass. At the similar time, sodium ions exit from the glass compound. Here the potassium (K) ions are larger than the sodium (Na) ions. So a compressive stress occurs. That stress is really an honest factor and stops the glass from breaking on flaws.

Chemical Strengthening Process:

Chemical tempering strengthens the glass by putting the surface of the glass into compression by “stuffing” larger sized ions into the glass surface. During chemical tempering method, the glass is submersed in a bath of molten salt at prescribed temperatures. The heat causes the smaller ions to depart the surface of the glass and bigger ions present within the molten salts to enter it. Once the glass is off from the bath and cooled, they shrink. The larger ions that are currently present within the surface of the lens are crowded along. This creates a compressed surface, which results in stronger glass that’s more resistant to breakage.

Achieving the specified compressive stress characteristics is time/temperature dependent. Gorilla glass, in contrast to most soda lime glasses, is not self limiting thorough of layer, thus smart time/temperature management is important for a stable method. Although Gorilla glass could also be chemically tempered at temperatures up to 460°C (Temperature vary between 390°C and 420°C) with the target salt temperature maintained to +/- 2°C. Tempering time should be controlled at intervals +/- 5 min.

Fluorosilane coating:

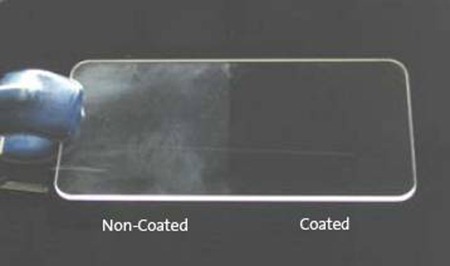

As people’s lives become busier and workplaces transcend the boundaries of office walls, the demand for mobile technologies continues to grow. With this transformation comes the need for a cover glass that promotes clarity while, also protecting and promoting the lifespan of display devices. The primary objective for development of this coating has been to enable the continued ability of a coated glass surface to exhibit superior optical clarity and mechanical reliability, service life, and, most importantly, the glass surface must function for its purpose.

By applying Fluorosilane coating over the glass sheets prevent fingerprint appearance and enable ease of fingerprint removal from the everyday products like Dirt, Oil, Soap, Lotion, Butter, Ketchup etc. Now the coating improves the clarity and optical performance better than soda lime glass.

The latest generation of Gorilla Glass is claimed to be 20% thinner, and more responsive to touchscreen commands than its predecessor. This implies that the screen pictures are probably brighter and slimmer line in style.

Gorilla Glass’s development coincided somewhat fortunately with the increase of the touch-screen smartphone; the best example is arguably the iPhone. However, handsets are only the beginning. The product / merchandise is experimenting with more thin and flexible sheets, and printing on glass to be used on custom – built laptops, Liquid Crystal Display Televisions et al.

—————————————————————————————————

Tagged with: cell phones with gorilla glass • Gorilla Glass Manufacturing Process • Gorilla Glass Material • Gorilla Glass Molding • Gorilla Glass molten salt bath • Gorilla Glass pdf • Gorilla Glass ppt • Gorilla Glass properties • Gorilla Glass protection • Gorilla Glass strength test • Gorilla Glass stress test • How is Gorilla Glass made • iphone 4 screens • iphone screen repair • laminated glass • new iphone screen • what is gorilla glass