Sheet Metal Forming Basics and Processes

Sheet Metal Forming

Sheet metal forming involves a wide range of processes that manufacture parts for a vast amount of purposes, both seen and unseen. Sheet metal refers to metal that has a high surface area to volume ratio. Sheet metal work stock, used for sheet metal processes, is usually formed by rolling and comes in coils.

A distinction needs to be made between sheet metal and plate metal. Sheet metal is 1/4 inch or less in thickness, while plate is over 1/4 inch in thickness. Sheet and plate have different applications. Plate is generally used for larger structural parts like boilers, turbines, bridges and ships. Sheet metal is used in the manufacture of cars, trains, aircraft, farm equipment, office equipment, furniture, house appliances, computers, machine components and beverage cans to name a few. Some of the sheet metal manufacturing processes may be applicable to plate metal as well, even though the work piece is referenced only as sheet metal. However plate, particularly thicker plate, will provided its own set of problems in processing. Therefore, some of the sheet metal operations discussed may not be applicable to plate.

Sheet metal manufacture is mostly performed on a press and parts are formed between two die. The top die is called a punch. Sometimes sheet metal parts are referenced to as stampings. Parts are usually economical and easy to mass produce. Sheet metal is usually formed cold, however warm or hot working of parts, (particularly plate), is possible. Generally for sheet metal applications there is essentially no change, or negligible change, in sheet thickness. For some processes like deep drawing, there is a slight and expected change in thickness, but this may also be neglected in most cases. Sheet metal manufacturing produces parts that typically have high strength, good surface and accurate tolerances.

Sheet Metal Mechanics

And Testing Methods

Mechanical behavior of metal is important to understand when manufacturing sheet metal products. The metal forming basics section provides information on this topic. Generally a desirable property for metals is a large plastic deformation before necking. When necking of the metal occurs, diffuse necking is preferred over localized necking. A high total elongation of the material before fracture is also desirable for sheet metal forming. Some metals such as low carbon steels and aluminum-magnesium alloys may experience yield point elongation. This uneven yielding of the material may produce stretcher strains or Lueder’s bands. These lines are actually small depressions in the material. Lueder’s bands may not be acceptable in situations where surface finish matters. Grain size, structure and orientation are also important in a sheet metal work piece. Grains will affect the properties of the metal as well as surface finish.

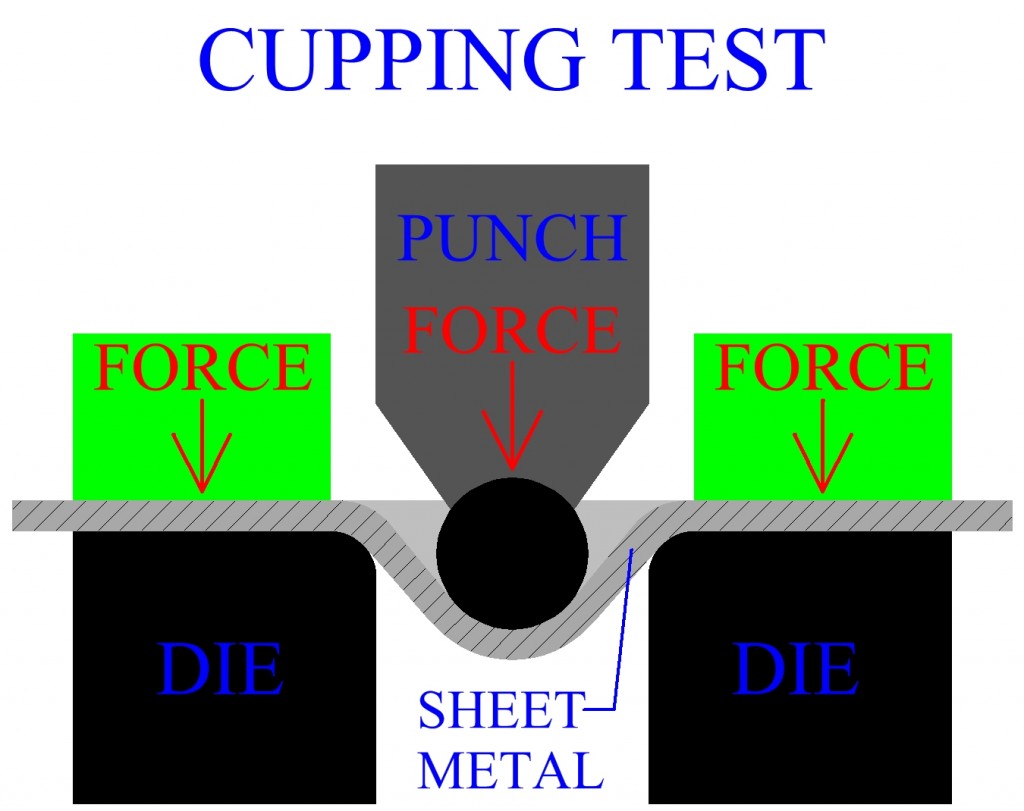

In addition to the standard tests for materials, (such as tension tests), there are tests that are used specifically to determine the formability of sheet metal. One common test is the cupping test. A specimen is secured over a round die cavity and a steel ball is pushed into the specimen until fracture of the material occurs. The greater the distance that the sheet metal can plastically deform before fracture, the greater the sheet’s formability.

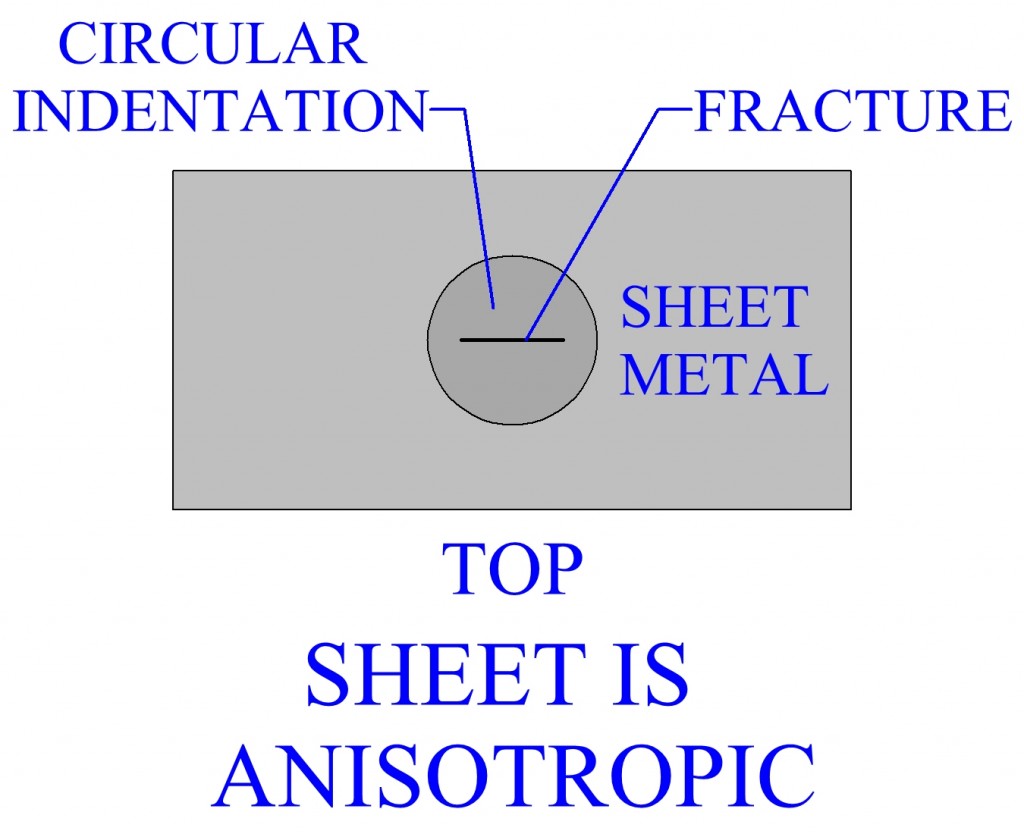

Anisotropy is an important factor in sheet metal forming. Anisotropy is the directional variation of mechanical properties. In other words, the material will react differently to stress applied in one direction than it would to the same stress applied in a different direction. If a sheet is isotropic, then its properties are the same in any direction. Cupping tests can be used to determine anisotropy. If the fracture occurring due to the applied force through the round ball is circular, then the sheet is isotropic. If a straight fracture occurs, this means that the sheet is anisotropic.

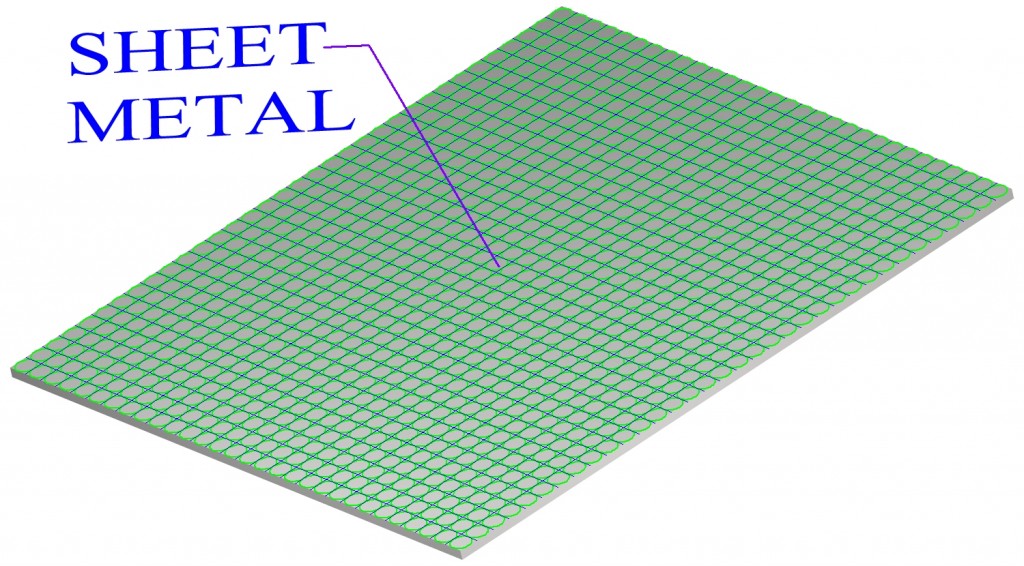

Many sheet metal operations will create a complex distribution of forces. Material elements experience different amounts, and proportions, of bi-axle stress and strain depending upon their location within the work. Sometimes a sheet metal is tested over a range of different bi-axle forces. A grid with inscribed circles is printed on the specimen. The grid and circles will deform with the metal.

Tests can then be performed to determine the metal’s reaction to different combinations of bi-axle strain. Failure and safe zones for combinations of major and minor, (the two directions), strain can be established. Forming limit diagrams can then be created to display this information graphically. The forming limit diagram is a useful reference for sheet metal manufacturers.

Sheet Metal Classification

There are 3 major classes of processes of sheet metal working.

Cutting: Cutting is the use of shearing forces to remove material from a work piece. Technically not a metal forming process, but of extreme industrial importance.

Bending: Bending is the forming of a sheet metal work about an axis.

Deep Drawing: Deep drawing is the forming of a cup or box with a flat base and straight walls, from a sheet metal blank.

Other Processes: Other sheet metal working processes such as ironing, spinning, rubber forming and high energy rate forming are coming soon in next posts..

Leave a Reply